From equipment such as belt weighers to vehicles such as production drills and driverless trucks, innovative mining technologies have reached an astounding level. A modern Australian coal mine is incomparable to that of a century ago. Continual application of innovation is important to the Australian mining sector and Australia. It is a big part of our economy and generates a significant part of our wealth.

Modern Australian coal mines are incomparable to coal mines from a century ago

Overview of the Australian mining industry

The Australian mining industry comprises nearly 400 operating mines. The mines are underpinned by large capital investments and generate massive export earnings. The industry is a global leader in the production of many minerals, making it a key contributor to the Australian economy.Why it is is important to apply innovative mining technologies

In recent times global economic growth has dramatically increased demand for metals and minerals. Innovative mining technologies and processing techniques have made possible the extraction of previously unviable deposits. When extracting valuable metals and minerals from the ground, new technologies have brought:- Incredible operational efficiencies

- Massive increases in output

- Greatly improved operational safety

- Increased mine profitability.

Examples of innovative mining technologies in Australia

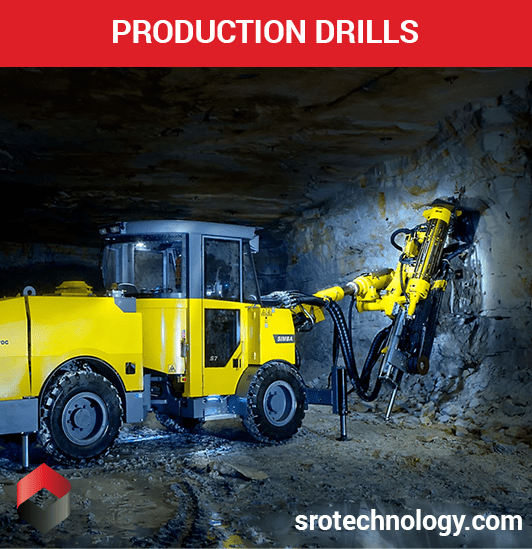

As a key element to improving economic opportunities in Australian mining industry, we will cover three examples where innovative mining technology has been applied. Investing in advances such as these is vital for achieving the business objectives pertinent to the mining situation. The examples we provide are generally specific solutions, however they give an insight into how far technology has improved. If you are working in the mining industry, we suggest you look into innovation that may exist and be applicable to your particular situation. You may be surprised by what is out there!Production drills

Some of the most impressive pieces of equipment used in the industry today are production drills. They provide fast, accurate drilling in tunneling and cavern excavation. A production drill comprises several platforms used to drill holes into a rock face which will then be loaded with explosives. The platforms are fixed onto a chassis that supports an operator cabin and engine. These are designed for multifaceted operations and highly accurate drilling.Features and capabilities

The latest production drills are powered by diesel hydraulic engines with over 200kW of power. They carry large compressors (four or more cubic metres is size) and hold water tanks whose capacity is at least 1,000 litres, so they can carry out air-mist flushing. The operator cabins are well insulated to minimise noise and vibration. They are typically four-wheel-drive and articulated in the centre to maximise ability to balance while drilling or when travelling at a rapid pace. Production drills are versatile and able to carry out crosscutting, bolt-hole drilling and extension drilling operations. They are compact machines, less than 15.0 metres in length, able to:- Drill hole lengths over 6.0 metres

- Turn in 4.5 metres of width

- Tram or drill in width of 3.0 metres and height of 3.6 metres

Innovative mining technologies used in Australia include production drills

Driverless haul trucks

Beyond the excavation area, new technologies have been enabling improvement and optimisation in the haulage process. Driverless haul trucks are used extensively in large mines to haul excavated material from the mine directly to the processing facility. In fact, Australia is the world leader in this technology. These trucks are operated with a central controller and a supervisory system instead of a driver. They use predefined GPS courses to automatically navigate roads and intersections, and at all times know actual locations, speeds and directions of other vehicles. The driverless haul trucks weigh over 200 tonnes, typically carry payloads of 300 tonnes, and are powered by engines with more than 2,000 kW output. Australia was the first in the world to have mines in the Pilbara haul all their iron ore in this way. Josh Bennett, tRio Tinto Pilbara mine Operations Manager, said he has workers driving the trucks remotely from the Yandicoogina and Nammuldi mines right through to Perth, over 1,200 kilometres away. Josh said, “What we have done is map out our entire mine and put that into a system that works out how to manoeuvre the trucks through the mine. In this way, we have taken away a very high-risk role in which employees were exposed to fatigue.” Australia dominates this technology and operates 400 of the world’s 500 driverless haul trucks in surface mines. The number of operating driverless haul trucks is expected to triple within the next few years.

Innovative mining technologies used in Australia include driverless trucks

Belt weighers

Mine operators need to know, without disrupting the operation, exactly how much bulk material has been extracted by production over any given period. There can be no denying the importance of equipment that provides accurate, non-disruptive continuous weighing of extracted materials. Belt weighers do this and can measure several hundred tonnes of material per hour. This allows operators to report mining extraction progress and ensure the mine is meeting production quotas.What are belt weighers

Belt weighers are used to measure the mass of bulk material being transported by troughed conveyor belts. These conveyor belts typically transport material from the mining area for loading or processing. The belt weighers are inserted at key points along the conveyor belt system to continually report the mass of material being transported. They become an active part of the process flow control. Belt weighers are also known as dynamic scales, belt scales, in-motion weighers and conveyor scales.How belt weighers work

A belt weigher replaces a small section of the support structure of the conveyor belt. It is typically used to replace one or more sets of conveyor idler rollers. The new support structure is mounted on load cells. The load cells measure the mass and another device measures the belt speed. These measurements are fed into a device which calculates the mass of bulk material being transported by the conveyor belt.Innovation in remote monitoring

SRO Technology, an Australian company, is a market leader in the design and installation of belt weighers and are able to integrate remote monitoring into belt weighers to improve the maintenance cycle. Remote monitoring allows access to information and the ability to make decisions from anywhere. Typical features include:- Use of 3G plug and play hardware

- Easy access online dashboard

- Monitors outputs such as speed, rate, belt loading

- Resettable totals help to identify issues quickly

Innovative mining technologies used in Australia include belt weighers

Contact us if you are investigating innovative mining technologies such as belt weighers

SRO Technology are experts in the design and installation of belt weighers in Australia. Our team has much experience in delivering best-fit solutions that can vastly improve operations by:- Minimising calibration time

- Maximising accuracy

- Minimising downtime

Recent Comments