X-Ray Machines

With a range of customisable solutions for the specific inspection needs of customers, our X-ray detection systems offer a cost-effective and practical solution to product recalls.

Responsible food production is dependent on quality product inspection. Food processors know the importance of dynamic detection in the upkeep of quality. As any form of contamination that compromises food safety jeopardises the legality of operations, the company’s reputation and its bottom line.

That’s why SRO Technology supplies only the most reliable and accurate X-ray detection systems on the market. Through our product inspection solutions, physical contaminants can be identified, thus avoiding legal and reputational repercussions.

Why choose an X-ray detection system?

Being able to detect contamination early can not only prevent reputation deterioration but also save your company money. Preventing recalls and reducing the chances of legal action are essential to maintaining a healthy organisation.

X-ray inspection systems are designed to accurately and dynamically detect physical contaminants, such as glass, metal, stone and other solid particles as well as a range of quality checks within packaged, unpackaged and bulk goods in the food industry.

SRO Technology’s X-ray detection systems apply the Hazard Analysis and Critical Control Points (HACCP), which means businesses can rest assured of the standard of quality control.

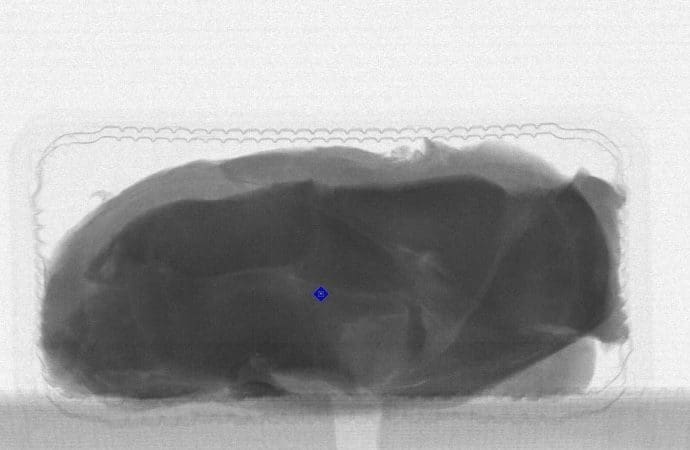

Radiographing using X-rays can help detect contamination from dense materials such as glass, ceramics, metal, stones, and similar materials. The system works by measuring the radiation produced by an electronic X-ray tube as it penetrates the solid bodies travelling, for instance, along a conveyor belt. The higher the density of an object, the darker the silhouette the imager produces.

X-ray detection systems can typically identify all the contaminants if their density differs from that of the product being inspected. Additionally, X-ray systems can detect variations in product integrity, such as missing products, air bubbles, shape deviations and disparities in weight.

Are X-rays safe?

X-ray detection systems expose employees and consumers to less radiation that a Trans-Atlantic flight, a full body CT scan, a dental X-ray and the natural radiation experienced while outside.

Using X-ray inspection systems can not only support product integrity and purity, but also improve the quality of the end product. It does not matter if you are packing confectionery and cereals or producing meat and sausage products, X-ray technology can help you produce superior products through a safe and cost-effective solution

Why choose SRO Technology?

SRO Technology has over 20 years of experience in product and material inspection stemming from working with a number of industries. From developing X-ray detection systems for mining companies to servicing instruments in the bulk materials industry, our experience transcends any one sector.

With experience and expertise developed through long-term exposure to a range of industries, SRO Technology is well equipped to handle your specific needs. Whether you are looking for a detection instrument to improve quality in a canning supply chain or in need of expertise on instrumental problem solving for a unique issue, SRO Technology can develop the best, most-pragmatic and cost effective solution.

If you need more information about the X-ray detection systems and how they can solve issues in a range of applications, it is important to talk to one of SRO Technology’s experts today. Contact a SRO Technology specialist today. For the New South Wales office call 61 2 9525 3077, the Queensland office on 61 7 3395 6136 or send an email to sales@srotechnology.com for further information.