Australia's mining industry faces a number of challenges that will only grow in the coming years. Recent studies from BDO and KPMG have shown that mining companies are striving to reduce reliance on diesel machinery, decarbonise mining practices and lower mining operations' economic impact overall. That's on top of the usual concerns about the sector's inherent volatility due to commodity prices.

With fears surrounding COVID-19 disrupting operations further, it's no wonder that fewer mining executives have a rosy outlook on the future of the industry. According to KPMG, only 38% of industry leaders are more optimistic about their organisation's growth potential than they were the year before.

Given all of this uncertainty, it's more important than ever that mining companies minimise operational risks and increase the productivity of their sites. With that in mind, conducting more routine site audits is a sensible response to recent trends and events in the mining industry. Such reviews can bring a number of issues to light that might otherwise go unnoticed.

Flag dangerous equipment malfunctions

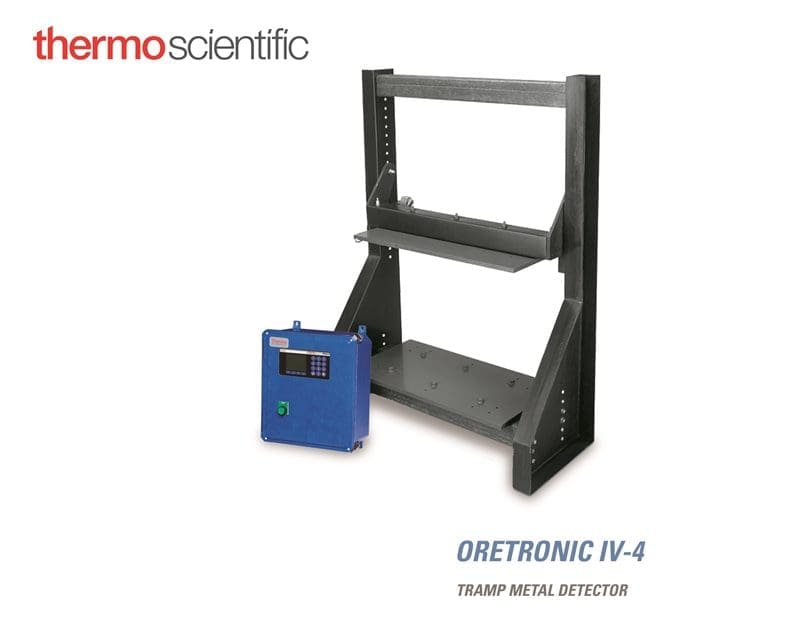

Mining facilities rely on precise instruments and robust machinery to keep operations running and protect the safety of workers. Tramp metal detectors are among the most critical mining equipment, as they ensure the quality and integrity of harvested materials while removing unwanted particulates.

Normal mining operations can wear down even the most durable machinery, breaking off excavator teeth, bolts, nuts and other metal fragments. Those pieces often get mixed in with processed materials and funnelled into machinery that is not equipped to handle them. Loose metal fragments could damage mining equipment and disrupt site productivity. In worst-case scenarios, those incidents could injure on-site personnel.

A thorough site audit will check that all tramp metal detectors are working properly and are able to reliably spot errant metals on conveyor belts before they reach processing equipment.

Improve site output and productivity

Conveyor belt scales are another important component to mining facilities, weighing and measuring harvested materials to check that the right volume is fed into processing equipment. When these figures are off, machinery may become overloaded. If mined ore and metal is to be blended with other materials for further processing, a faulty conveyor belt scale could lead to a subpar final product.

Reviewing the performance of this equipment will help mining companies maximise their output and improve quality assurance practices. With so much focus on reducing operational costs and increasing mining efficiency, site audits should be conducted on a regular basis to ensure that every facility is running at a high level.

Site audits also help prevent catastrophic production stoppages resulting from equipment failure. If any piece of machinery fails, it could take weeks for a new part to be obtained, installed and configured. Every minute that a site is unable to function is lost productivity and revenue for the organisation.

Need to schedule your next mining site audit? SRO Technology's experts are available to conduct on-site reviews that shine a light on the most pressing issues impacting your mining operations. Contact our team today to find out more.

Recent Comments