Calibrating Measurement Equipment

All measuring devices degrade in accuracy over time, often due to the regular wear and tear of frequent use. Depending on your environment, changes in the accuracy of equipment may also be caused by electric or mechanical shock. Calibrating measurement equipment is the process by which standard measurements are compared to the measurements of your devices to ensure consistency. It’s of the utmost importance that you have your equipment regularly calibrated for the following reasons.

1) Maintain industry compliance and consistency

Regardless of what industry you work in, there’s a pretty good chance that any measurement equipment you use is subject to regulatory compliance. Much of the time, using equipment that doesn’t meet these standards can incur fines. Furthermore, if you’re using multiple measuring tools it’s important that they are consistent with each other to ensure the best final product.

2) Reduce costly errors

If your operations result in something being over or under the standard weight, this can cost you in more ways that one. As previously mentioned, underweight production can lead to fines since you are providing the consumer with less than advertised. If you’re producing more than what is needed you could either end up with a large amount of unwanted product, or be over supplying your customers for the same price, reducing profit.

3) Eliminate safety risks

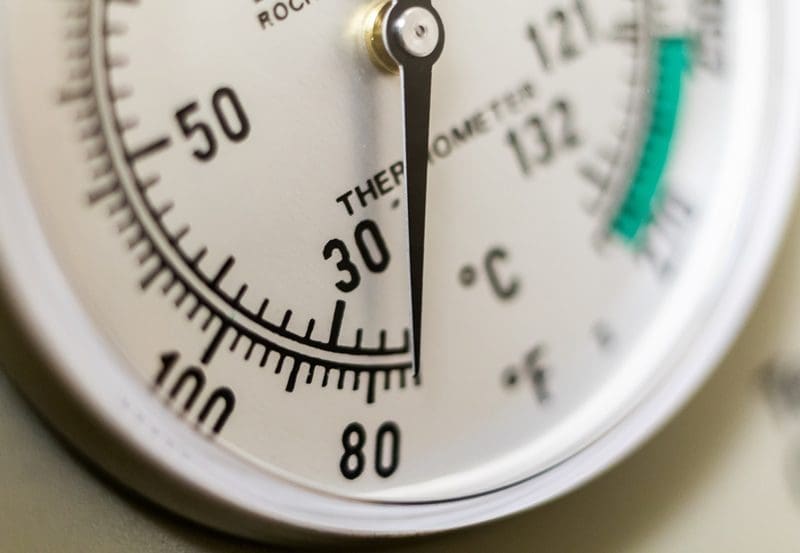

Uncalibrated equipment can also lead to safety risks in some situations. For example, if you have cold storage areas that are required to remain at a certain temperature, and that storage area is too warm – the food might spoil, leaving your staff or consumers at risk of contracting foodborne illnesses. Equipment that is not professionally calibrated in hazardous work areas could also have your staff risking electric shock or other injuries.

4) Minimise downtime

An ounce of prevention is worth a pound of cure, as the old saying goes. Maintaining regular calibration of your measuring equipment is far more efficient than having to repair this machinery if it breaks down. A specialist from SRO could identify potential problem areas before they throw a spanner in the works, ensuring your operations continue to run smoothly.

5) Keep your customers satisfied

If your product is inconsistent your customers won’t be pleased with it, and if the inconsistency continues they will likely start looking for a replacement partner who can deliver what they promise. This can hurt your business as well as your reputation, so it’s worth your while to ensure that you’re running a consistent and profitable operation.

For more information on measurement device calibration or our maintenance and calibration services, get in contact with SRO technology today.

Recent Comments